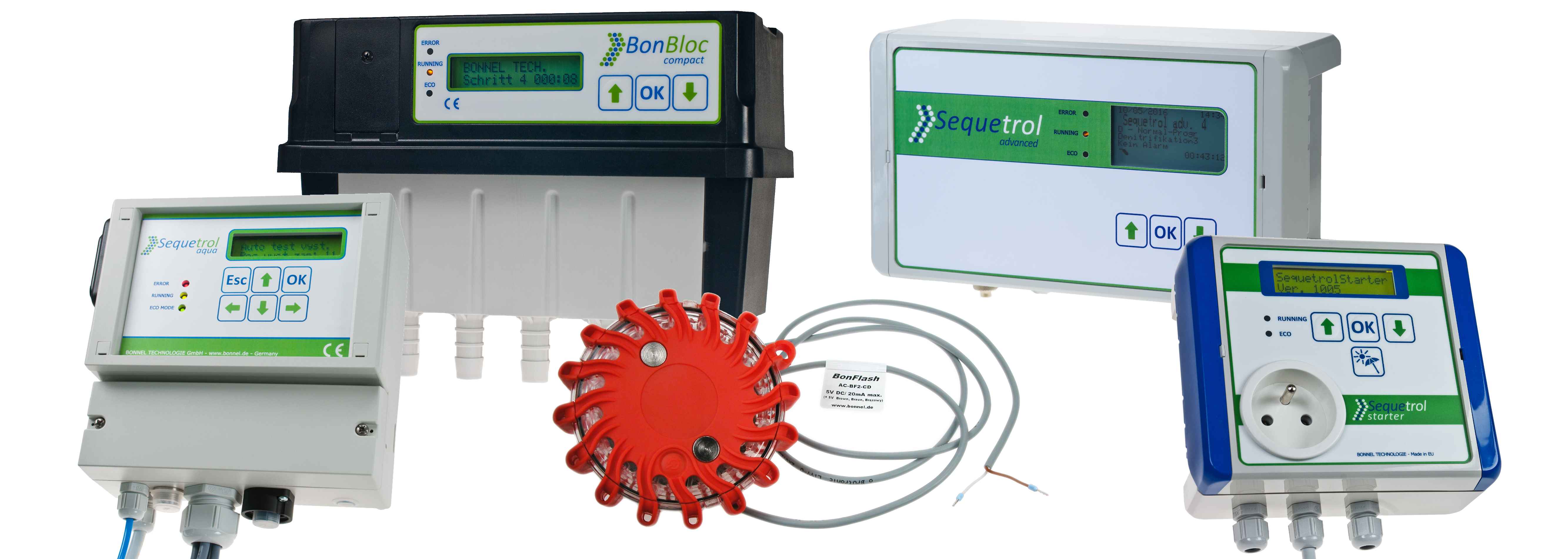

SEQUETROL IoT

Leistungsfähige Steuerung für SBR & kontinuierliche Anlagen, mit on-board WLAN und GSM als Module.

Unterschiedlicher Hardware-Ausbau und Gehäuse sind auf Wunsch verfügbar.

- Different hardware versions

- Up to 8 relay outputs, up to 3 digital inputs

- 4-20mA analogue input

- Graphical LCD

- Wi-Fi and webserver on-board, GSM as an option

- Water-level control for multiple tanks at multiple levels using pressure sensor

- Operate it by phone / tablet / touchscreen via browser (no app installation required)

- Connect into the world of PLC / SCADA via HTTP-REST

- Receive an email in case of any problems

- Run SBR and continuous processes parallel in one control unit, e.g. for duplex buffer-pump operation

- Measure water level by pressure sensing - via different airlifts / diffusor / bubbling-in

- Build even a complex wwtp with 8 relay outputs, 3 digital inputs, a 4-20mA analogue input and optional current measurement

- Program your process and menu on your own with the user-friendly and fast PC tool MenuMaker

- Analyze your plant using the detailed event log showing all relevant parameters, including pressure, in– and output states, remaining times etc.

The Sequetrol® IoT belongs to a new generation of control units developed to meet the requirements of the Internet of Things (IoT) and Smart Home. It combines the possibility to handle even the most complex sewage treatment processes with connectivity and remote operability.

The integrated webserver of the IoT controller series allows you to operate the treatment plant and to access all information with any browser.

Imagine, you’d like to service a plant and the owner of the building is not at home—simply access via Wi-Fi without entering the building.

Imagine you would like to operate a big plant with a touchscreen—simply add a standard tablet to the control cabinet and connect via Wi-Fi.

Imagine, your plant has some troubles and you don’t like to go hundreds of kilometers—simply connect via GSM and operate and analyze the plant.

REST using JSON over HTTP is a widely used standard for M2M communication. The control unit can thus be integrated into any code base that can communicate over HTTP, including .NET, Java, Python, scripting environments like PHP or JavaScript, and more! Like this, an efficient data exchange between the control unit and telemetry servers, PLC and SCADA devices is possible.

The innovative water-level sensing by pressure measurement allows cost-effective detection of pre-set water levels without the use of failure-prone float-switches.

With the Sequetrol® IoT there are no restrictions to your ideas. BONNEL’s PC software MenuMaker 4 enables you to program even the most complex processes and menus without being a programmer. The IoT controller supports multiple, connected programs, calculations within the process, analogue water level evaluation, automatic switching-off of airlifts, user defined alarm conditions, timers, counters and much more.

The IoT platform can help you to create new business models.

You want to rent your plants? Block the plant automatically when no payment is arriving.

You want to compete with big plants? Connect to SCADA and offer touchscreens.

You want to reach remote areas? Control and monitor your plant remotely.

You want to do PPP or provide cleaning as service? Prove your plant is running well connecting sensors to the analogue input and transfer all data to telemetry servers in the cloud.

The optional analogue input can be used for a further optimization of the wastewater treatment process. Properties, such as the turbidity of the treated water can be analyzed.

Up to four external digital signals can be monitored and processed within the control algorithm.

Up to 8 relay outputs for 230VAC offer a comfortable connection of solenoid valves, diaphragm blowers, submersible pumps or other loads.

The optional GSM module can be used to monitor the plant together with the BONNEL Aquavisor® telemetry server.

All electrical connections are made using reverse polarity protected plugs with IP54 rating. Of course the type of connectors can be changed according to customer requirements.

The extent of the system functionality and the design of the front panel of the Sequetrol® control unit can be tailored to match your individual needs.

The Sequetrol® advanced IoT is equipped with features as acoustic signaling of predefined conditions, rechargeable batteries to signal mains failure and non-volatile EEPROM memory for programs, event logs and an electronic operating book.

| Attribute | Value |

| Dimensions (l x w x h); weight | 166mm x 182mm x 83mm; 1.2kg |

| Ambient temperature | -20°C to +55°C |

| Protection classification / UV-Resistance (casing) | IP 53 / UV-resistant casing as option |

| Functions, sequence program, alarms, GSM communication, display messages (also multilanguage) | All according to customer request and requirement. Sequence programs are designed and adapted by means of a clear and easy-to-use PC‑software MenuMaker 4 |

| Display / LED | Backlit graphical LCD (128 x 64); 3 LED (colors as requested) |

| Outputs | Up to 8x 230VAC, 350VA relay outputs (max. total current 725VA) Digital output for alarm forwarding or communication 5VDC alarm lamp output for BonFlash alarm lamp (battery-backed) |

| Signal-inputs | 3x digital inputs; analog input 4-20mA; pressure sensor 0-400mbar; current sensor *) |

| Data interface | USB; Wi-Fi (AP and/or STA mode); GSM (2G) *) |

| Power backup during mains failure | 2x AA rechargeable battery or *) alkaline battery plus gold-cap for RTC |

| Power supply | 230VAC, 6VA max. |

*) According to selected equipment, all details are without guarantee.

ČESKY

ČESKY  DEUTSCH

DEUTSCH  ENGLISH

ENGLISH